To enhance profitability, reduce costs, and promote sustainability, businesses can recover valuable metals from e-waste like Copper, Silver, Gold, Nickel, and Cobalt. This not only generates sustainable revenue but also minimizes environmental impact by diverting e-waste from landfills and supporting circular economies.

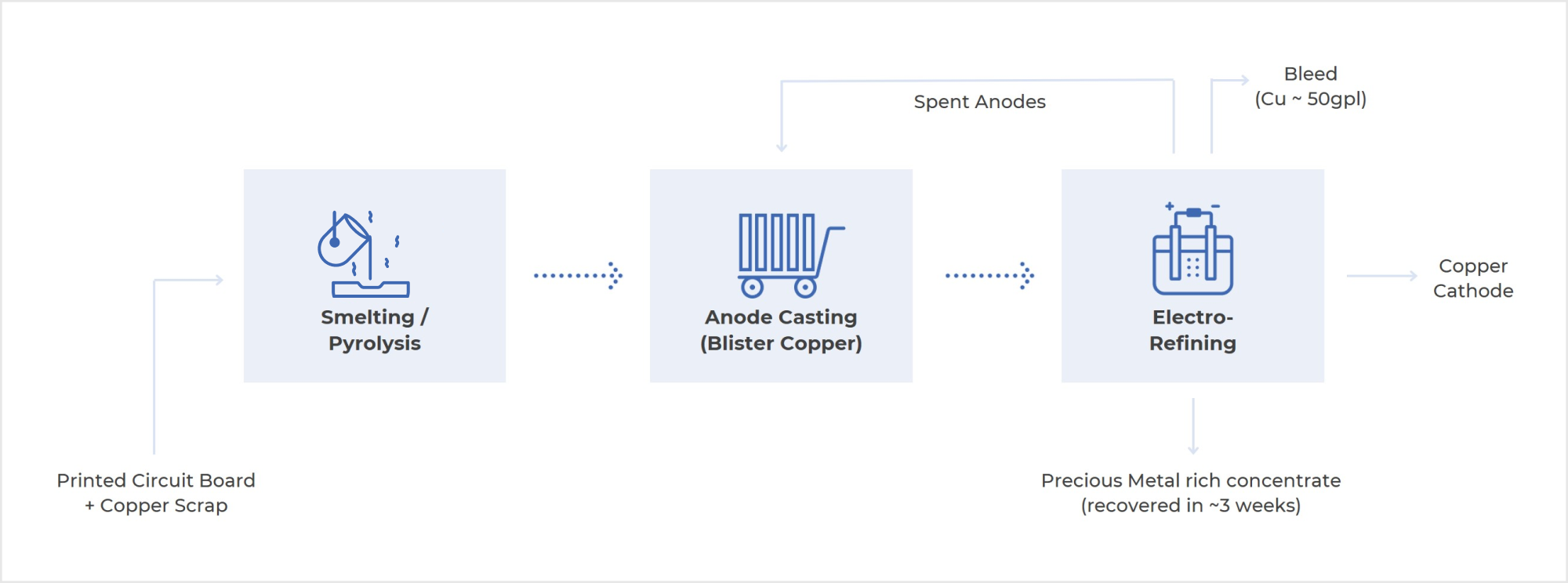

Smelting, commonly used for treating PCBs, incinerates and melts crushed PCBs in furnaces. However, this process only partially removes impurities, resulting in a low-concentration PGM alloy. Base metals need to be removed before processing the PGMs. Smelting has high energy consumption and poses risks of dioxin formation and toxic releases.

An additional required step in e-waste processing is electrorefining. The anodes are casted from smelted alloy, and pure copper cathodes are produced in electro-refining cells along with anode slime containing precious metal. This process takes about 3 weeks to liberate the precious metals and requires recasting spent anodes after electrorefining. Additionally, bleeding is necessary to maintain the quality of copper cathodes and remove impurities.