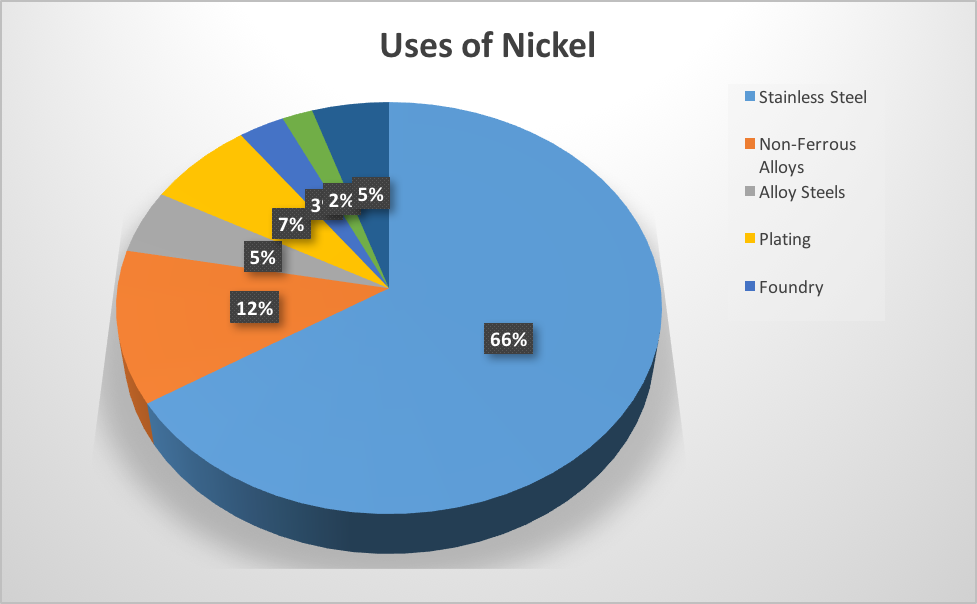

Nickel powders are widely used in industrial applications worldwide, such as rechargeable batteries, manufacturing and powder metallurgy. In some cases, nickel powders are used to add a magnetic feature to a particular material. Nickel can be used in electroplating and coinage industries as well. But there is more to nickel powder, and there is something that you have probably never heard about until now.

Topics: metal finishing, Advanced Metal Powders

The future of clean energy and its relationship to electrolytic metal powders.

I recently learned that metal powders have the potential to be the future of renewable energy sources. This is a relatively new venture, and an area of interest for us, here at emew, since producing metal powders is something we do daily. I wanted to explore the topic of the production of metal powders and explain more about how they are produced to create this renewable fuel source.

Topics: metal powders, Advanced Metal Powders

Five Things You Should Know About Metal Powder Production

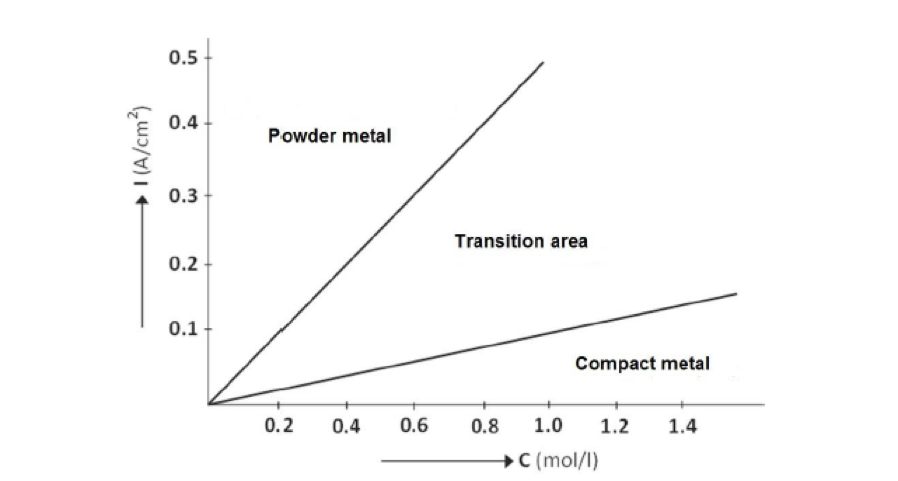

In electroplating, powders can be a very bad thing, but sometimes bad can be good. We are going to discuss doing a ‘bad thing’, but doing it consistently well.

Topics: metal powders, Advanced Metal Powders

Nickel and Nickel Powders

Topics: metal recycling, Advanced Metal Powders