Customer Engagement

We offer a range of pre-sale services to help our customers evaluate the best options for their process needs including:

- Feasibility Studies

- Testing of solutions and materials

- Pilot plant demonstrations

- Trade-off studies

- Process evaluation and optimization

- Efficiency improvements

- Sensor installation and data collection

Let us know how we can help you with clean technology solutions for environmental stewardship, metal recovery, energy efficiency, and wastewater treatment.

Procurement Alternatives

Are you looking to purchase a leading edge clean technology solution to install in a greenfield or brownfield operation? Perhaps your project has budget or other sensitivities that are better suited to alternative funding arrangements? We are confident that emew has the right solution to meet your specific requirements.

Equipment Sales

We have a wealth of experience to design and supply quality built systems for applications in environment stewardship, metal recovery, energy optimization and waste water treatment. We source components that seamlessly integrate with existing brownfield specifications or tie into larger greenfield projects with multiple vendors to facilitate installation and maintenance planning. Provide us with the specifics of your project and we will design and supply a system to meet your requirements.

Deferred Payment

We recognize that some projects do not easily fit within traditional financing models and may require more flexible alternatives. In these cases, emew offers deferred payment options that may be better suited to these sensitivities.

Value-Added Services

Contract Processing

Some projects may be better suited to contract processing that requires less start-up capital offset by an ongoing production-based fee schedule. An upfront commitment fee secures the equipment and engineering support to design and install the system in your facility. A production-based fee ($/kg or $/oz) is invoiced monthly or quarterly with predefined targets to be met. Contract processing also includes ongoing technical support, operating spares, and maintenance check-ups to ensure your system is running smoothly and that your objectives are met. Silver recovery and refining projects can be particularly well suited to this type of arrangement.

Feed Sourcing

With over 65 plants installed on 6 continents and 20 years in the business, emew has developed a vast network of contacts across industries. We are always on the lookout for new feed materials and opportunities to extract the most value from them. Many different types of residues, by-products or wastes containing copper, nickel, cobalt, tin, zinc, precious metals as well as complex mixtures of all of these are excellent candidates. If you have nonferrous and/or precious metal feeds, by-products, wastes or residues we are interested in speaking with you.

Project Partnership

Do you have rights to a small orebody or access to a complex metallurgical stream and are looking for a trusted partner? We are actively evaluating opportunities to contribute to engineering design, supply of process equipment, and a vast network of contacts for procurement and sale of products. If you are looking for a trusted technology partner, contact emew to see if there is an opportunity to work together in environmental stewardship, metal recovery, energy optimization, and wastewater treatment.

After-Sale Services

emewNet Management System

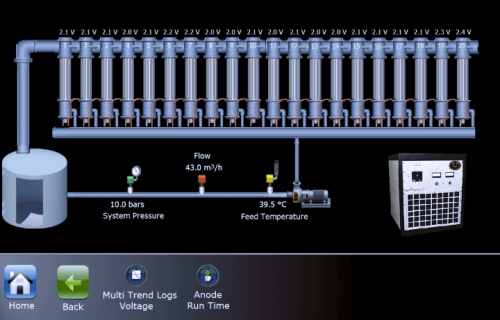

Continuous Performance Monitoring

Real-time, remote performance monitoring coupled with data collection and analysis ensure that emew’s state-of-the-art systems meet and exceed design specifications. System performance can be impacted by a sudden, unexpected event, or can happen slowly over time, long before any issues can be identified manually. Online performance monitoring provides the ability to identify trends and flag emergency situations immediately.

The proprietary emewNet system can measure not only variables such as temperature, pressure, and cell voltages, but custom-designed sensors also enable critical concentrations to be measured with the system responding accordingly. Just like monitoring a pulse and blood pressure reading in a hospital, our remote monitoring allows you to see what is happening inside the cell at all times. The real-time information is displayed graphically and with notifications of process irregularities.

Availability Maximization & Performance Optimization

When a system is down, production can be lost or discharge limits put in jeopardy. emewNet identifies trends and detects small changes over time that may impact performance. Online availability tracking with 24/7 performance monitoring provide management with a vital tool to determine if there are any chronic operational problems that can be addressed to improve online time and performance.

Performance optimization monitors plant availability but also reports on how each individual cell is operating to ensure that the plant is operating consistently and at optimum efficiency. By monitoring each individual cell, problems that occur occasionally such as hot spots, anode coating wear, current imbalance, and short circuits can be identified and rectified as soon as possible.

emewSense

Partnering with a leading manufacturer of process instrumentation, emew has developed proprietary sensors for copper, nickel, and silver ions. These sensors enable online, real-time determination of metal concentrations for the ultimate in-process control and operation management. When used in conjunction with emewNet, emewSense opens up a world of possibilities to fully automate your system resulting in cost savings, production efficiencies, and waste reduction.

Energy Audits

An energy audit ensures that the system is operating at optimum efficiency and lowest possible energy consumption. An energy audit is recommended on an annual basis to identify areas of energy loss and make recommendations for improvement including:

- Solution characteristics leading to low current efficiency

- Optimum operating windows according to feed characteristics and current density

- High numbers of short circuits lead to loss of efficiency

- Stray currents

- Poor conversion of AC power to DC (Usually when the plant is turned down)

- Poor current balance

- High pumping power

Safety Audit

All emew systems are designed with intrinsic safety features. Our safety audits are designed to ensure safe operating conditions but also to review the routine safety procedures that can be missed by someone operating the system day in and day out. The safety audit includes:

- Review of routine operating practices with an emphasis on safety considerations for operators to ensure seamless start-up and shut down.

- On the spot training focused on the results of the safety audit

- Review of key system components and ancillary equipment

- Upgrades available to further improve safety performance

- Review and written response on near-miss situations (if applicable)

- Recommendations from customers on safety improvements to be reviewed and responded to by the emew design team

Anode Condition Management

Anodes are a bit like tires on a car: they will eventually need replacing. Just like tires on a car, it is important to have the correct anode coating for the operating environment and that the status of the coating and general anode condition are inspected from time to time. This will ensure that you are able to maximize the life of the anode coating and replace at the optimum time to maintain plant performance and minimize the cost of replacement.

Most of the time the anode coating can be replaced and emew has developed on-site testing methods to check on anode coating condition. Together with our anode coating suppliers, we have developed a knowledge base of the best coatings for various conditions as well as simple, low-cost replacement methods when it comes time to replace the coating.

Anode condition management ensures that performance is maintained at all times and the anode condition is monitored continuously by our online voltage monitoring system and interpretative software as well as regular physical spot checks on site. This ensures trouble-free plant operation and minimizes operating cost of the anodes.

Refits and Technology Upgrades

At emew, we are continuously striving to improve the technology and application base. Based on customer input on how we can improve the technology and support, we have worked with experts on our advisory board to push the boundaries of the technology further and even established a state-of-the-art development center to test our new upgrades before offering them to our customers. Some of the recent and upcoming upgrades include:

- Online performance monitoring

- New safer and acid resistant cell mounting plates

- New cell safety insulators

- High productivity cells with smaller footprint and step change in economies of scale

- Smaller, lower cost and more efficient rectifiers

Equipment Audits

We take immense care to ensure that our equipment is of the highest quality and standard, maximizing longevity to our customers. As with all equipment, routine assessments and preventative maintenance are vital to maximize workable lifetime and minimize depreciation.

Our audits include a complete assessment of your system with a certified emew technician arriving onsite, providing a thorough inspection, comprehensive analysis, detailed report and essential recommendations. These audits ensure your plant operates optimally and capitalizes on its full value for years to come. We can also perform audits on previously owned plants on behalf of the buyer or seller, and supply OEM replacement parts and commissioning services for relocation and start-up.