The average nickel content of the crust is estimated at 0.008 %. With such low content, it makes it obvious why nickel mining is such an important industry, and why the recovery of nickel and nickel recycling is becoming increasingly significant in our consumer-based society.

The efficiency of electrowinning any metal, including Nickel or Cobalt, depends on a variety of factors including the concentration of metal in the electrolyte, current density, temperature, pH, conductivity, impurities, and so on. If the electrochemical potential is sufficiently positive, these factors become less important. With Nickel and Cobalt, however, the slightly negative reduction potential means that it requires careful control of conditions to produce a harvestable metallic plate.

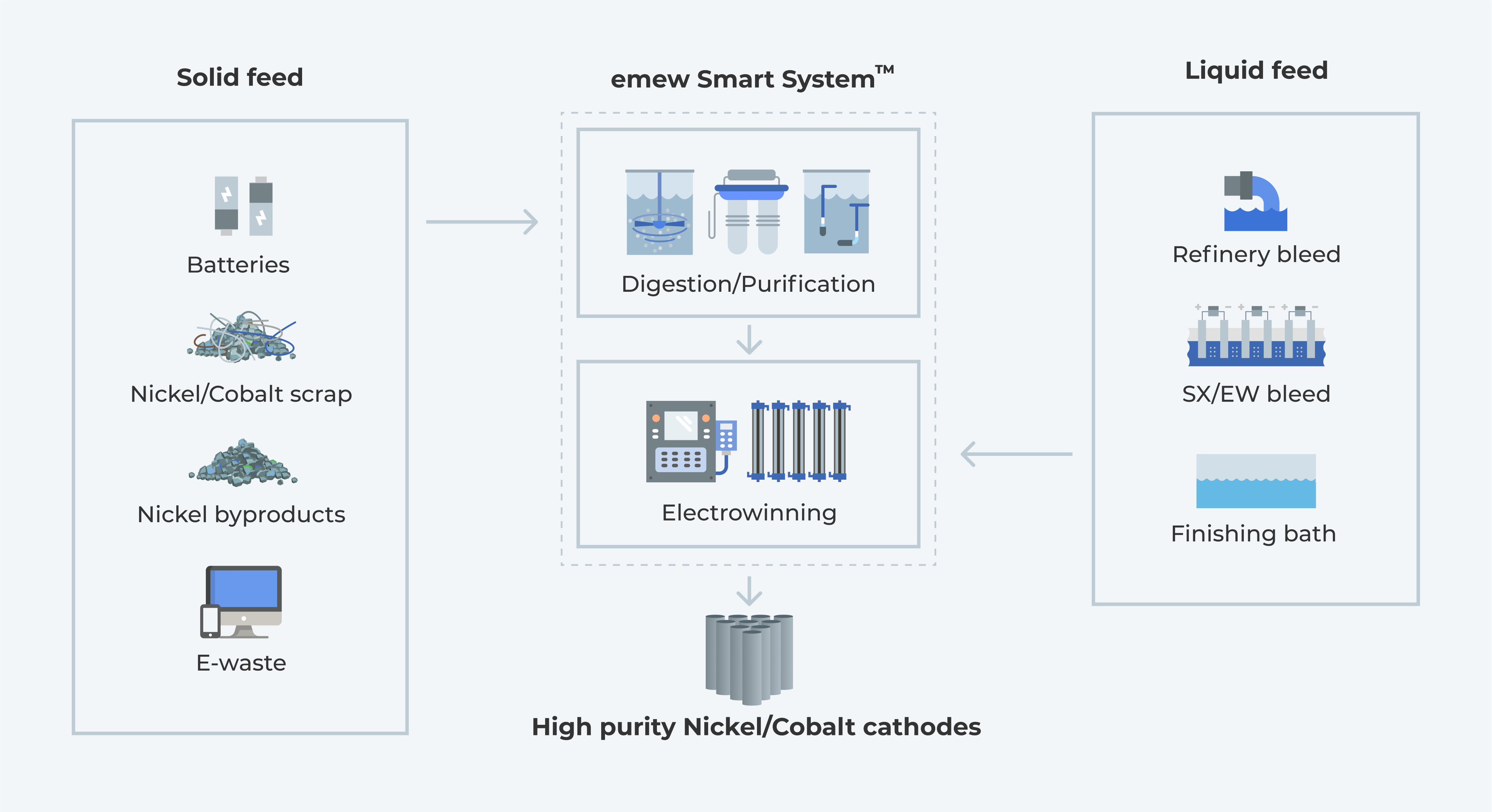

We have been able to revolutionize the way Nickel and Cobalt are electrowon, and with the clever combination of emew electrowinning and process methodology we are able to recover metals from a variety of feeds including E-Waste, Nickel/Cobalt scrap, Nickel by-products, batteries, refinery bleed, SX/EW bleed and finishing bath.