Copper removal from Li-ion batteries

Lithium-ion battery recycling is an important process for both environmental and economic reasons. However, the recycling process can be challenging, and copper removal is often a key step in the process.

Copper is one of the valuable metals that can be recovered from battery black mass during the recycling process.

The recovery of copper from battery black mass typically involves hydrometallurgical processing, which involves dissolving the materials in acid. This process is complex and requires specialized equipment and expertise.

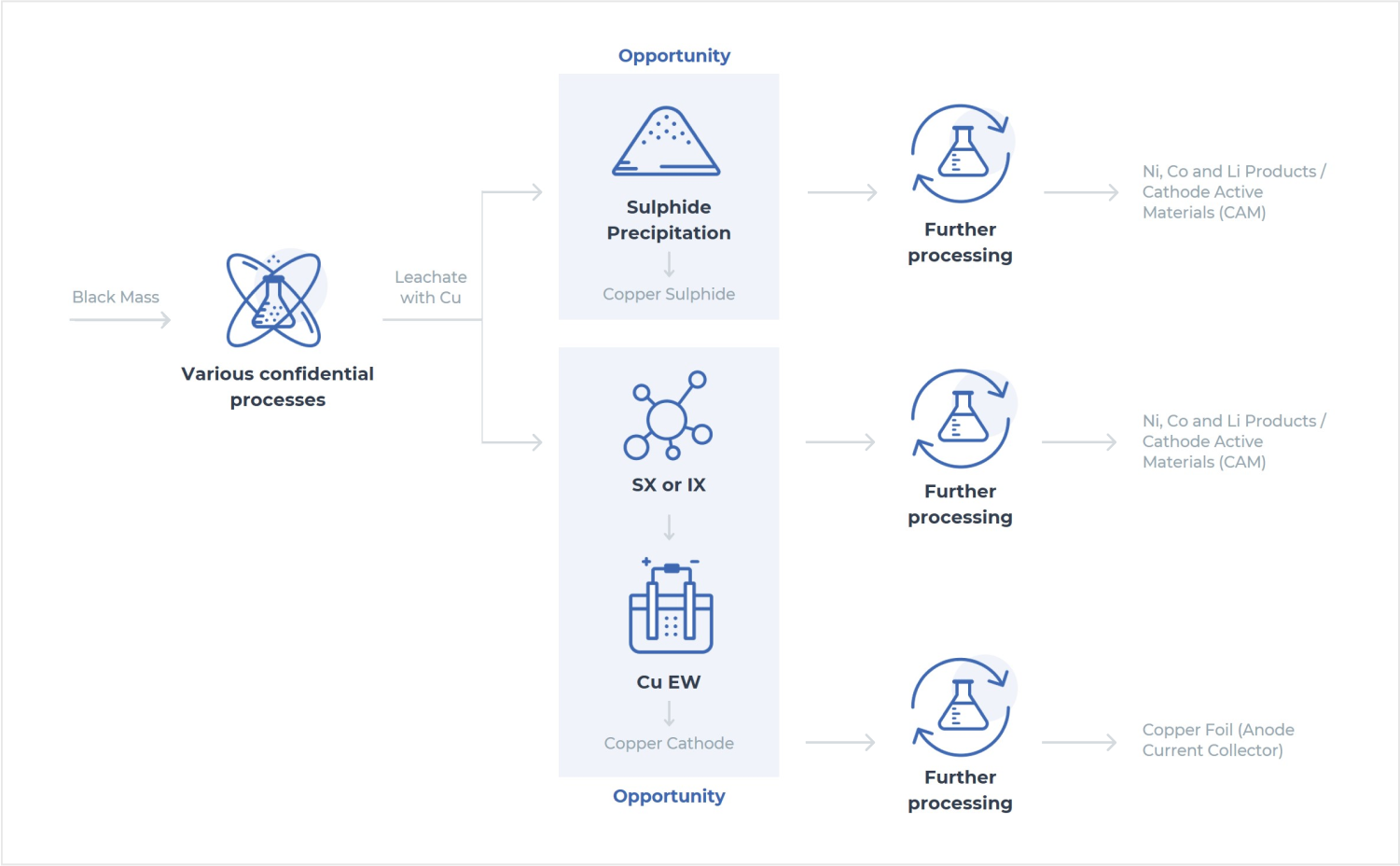

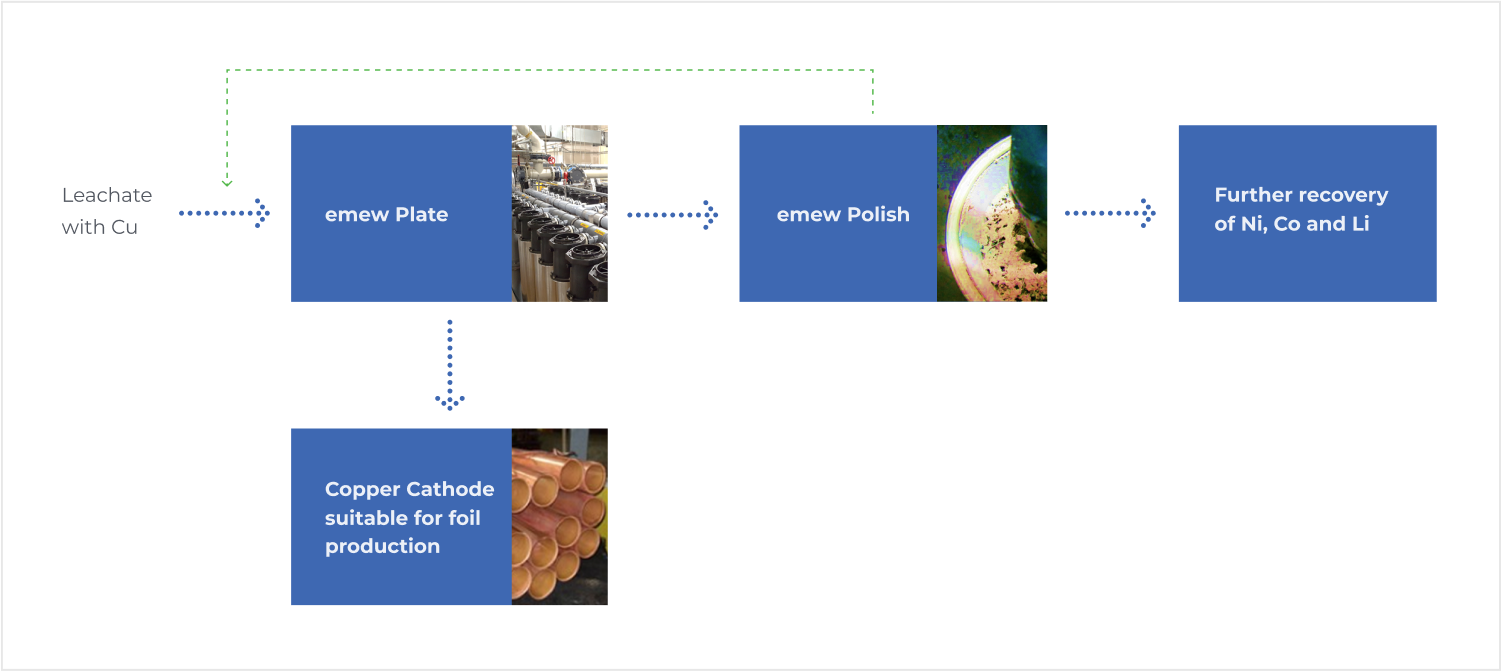

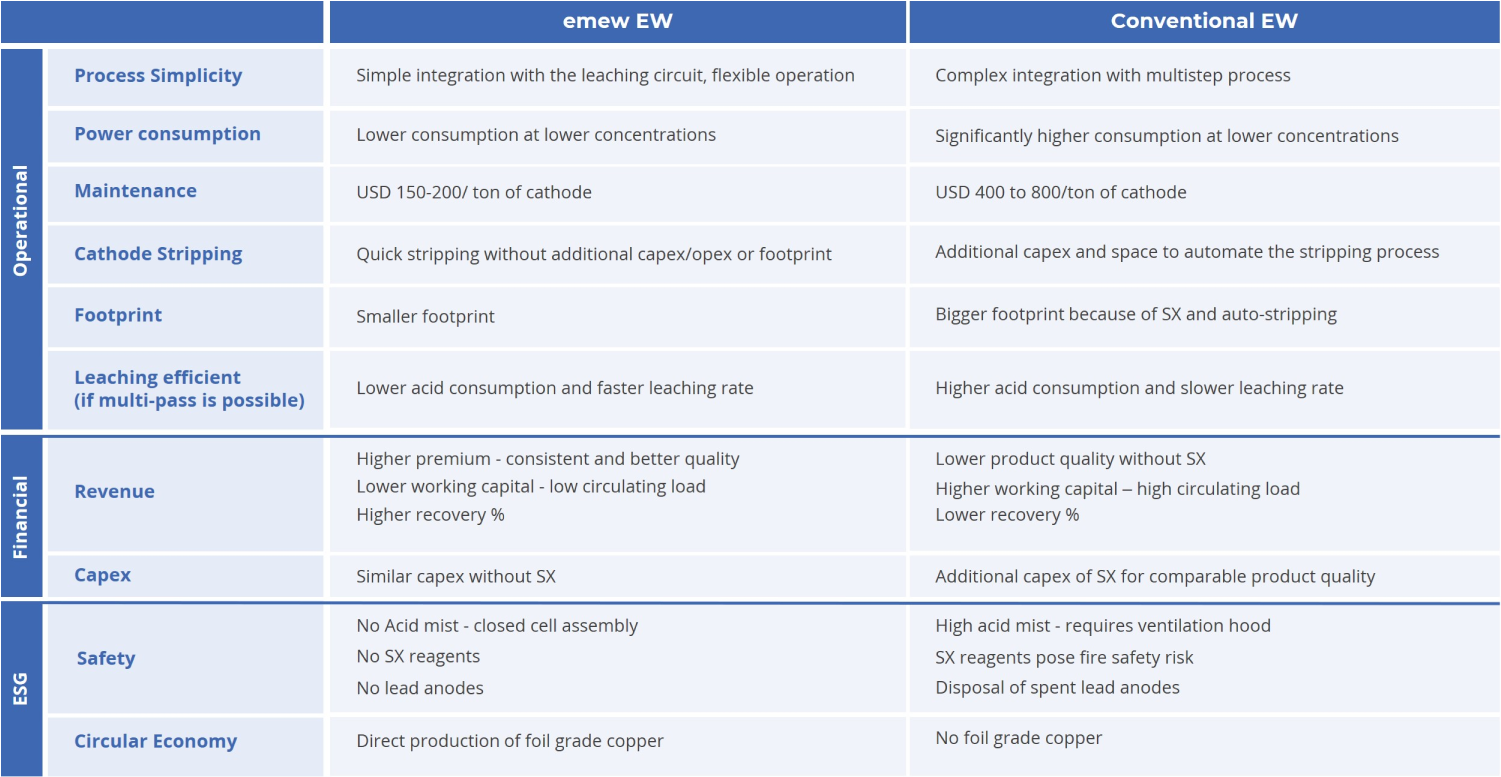

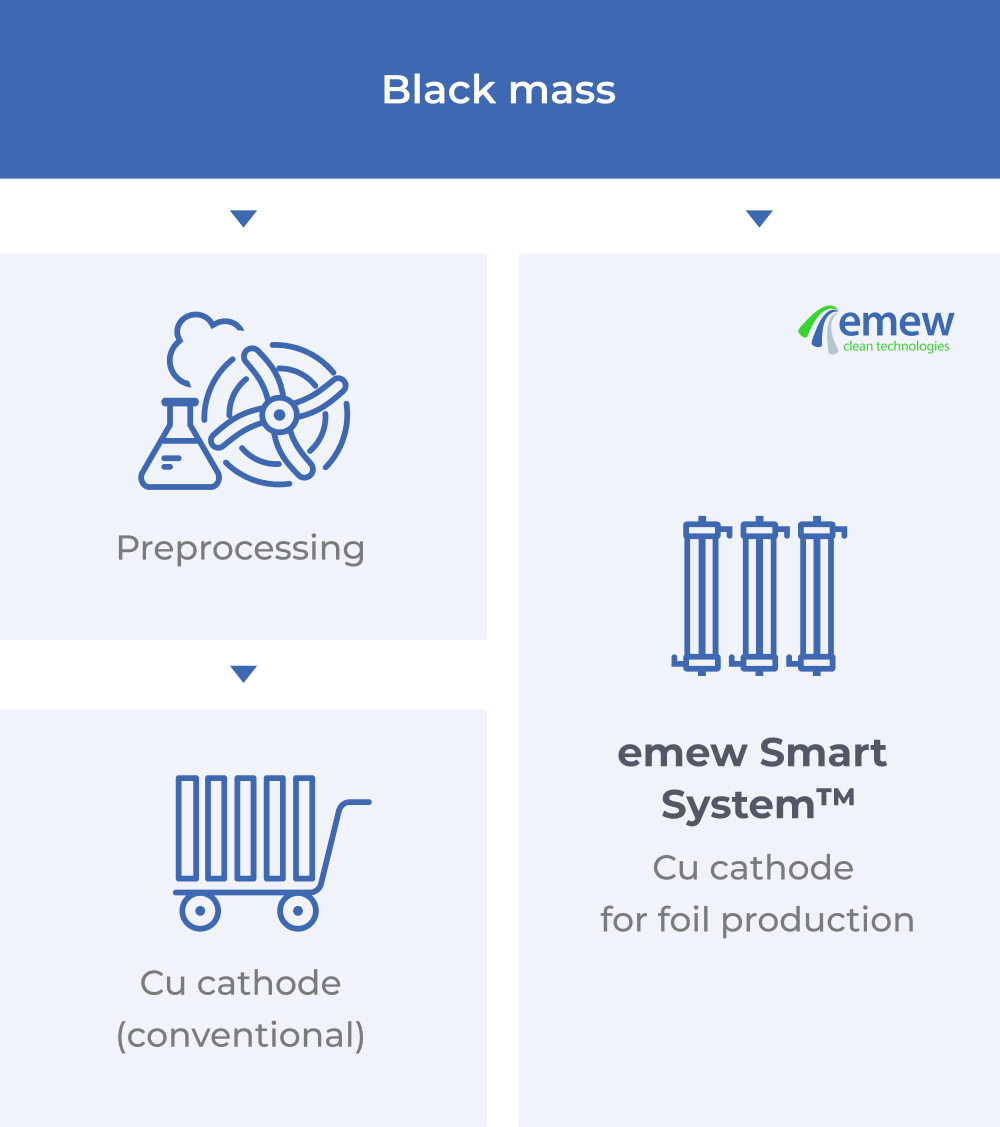

The solution offered by emew helps avoid SX/IX or Copper sulfide precipitation. It is a simple two-step method for copper recovery. The first step is to extract over 90% of copper selectively from the black mass leachate, transforming it into high-quality copper cathodes suitable for foil production. The balance of copper is then completely removed in the selective emew process to produce battery grade salts in the downstream steps.

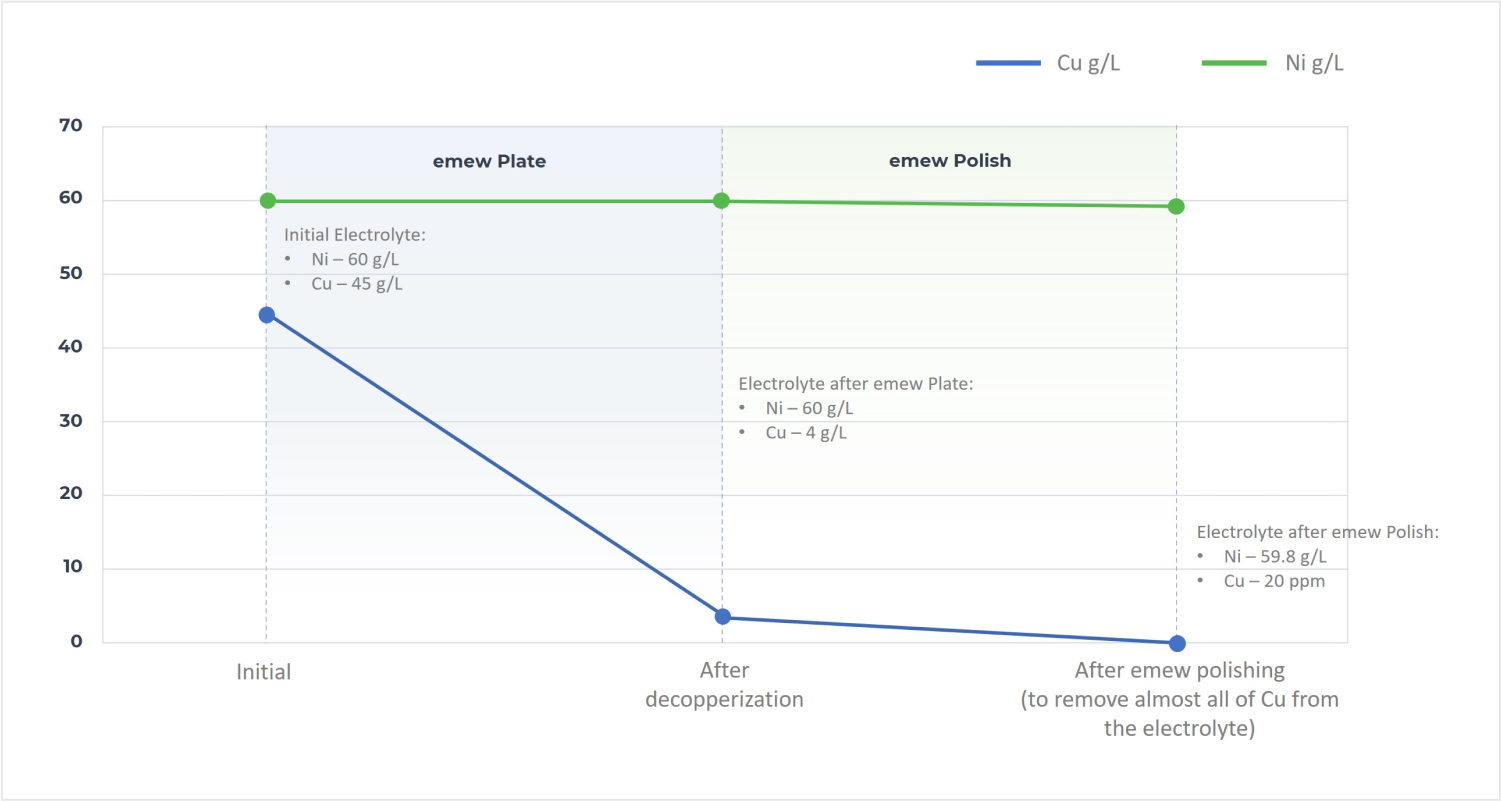

Overall selectivity achieved for copper removal from the black mass leachate:

A solution offered by emew is a simple and sustainable method for copper removal and cathode production from Li-Ion batteries black mass leachate:

Lithium-ion battery recycling is an important process for both environmental and economic reasons. However, the recycling process can be challenging, and copper removal is often a key step in the process.

Copper is one of the valuable metals that can be recovered from battery black mass during the recycling process.

The recovery of copper from battery black mass typically involves hydrometallurgical processing, which involves dissolving the materials in acid. This process is complex and requires specialized equipment and expertise.

The solution offered by emew helps avoid SX/IX or Copper sulfide precipitation. It is a simple two-step method for copper recovery. The first step is to extract over 90% of copper selectively from the black mass leachate, transforming it into high-quality copper cathodes suitable for foil production. The balance of copper is then completely removed in the selective emew process to produce battery grade salts in the downstream steps.

Overall selectivity achieved for copper removal from the black mass leachate:

A solution offered by emew is a simple and sustainable method for copper removal and cathode production from Li-Ion batteries black mass leachate: