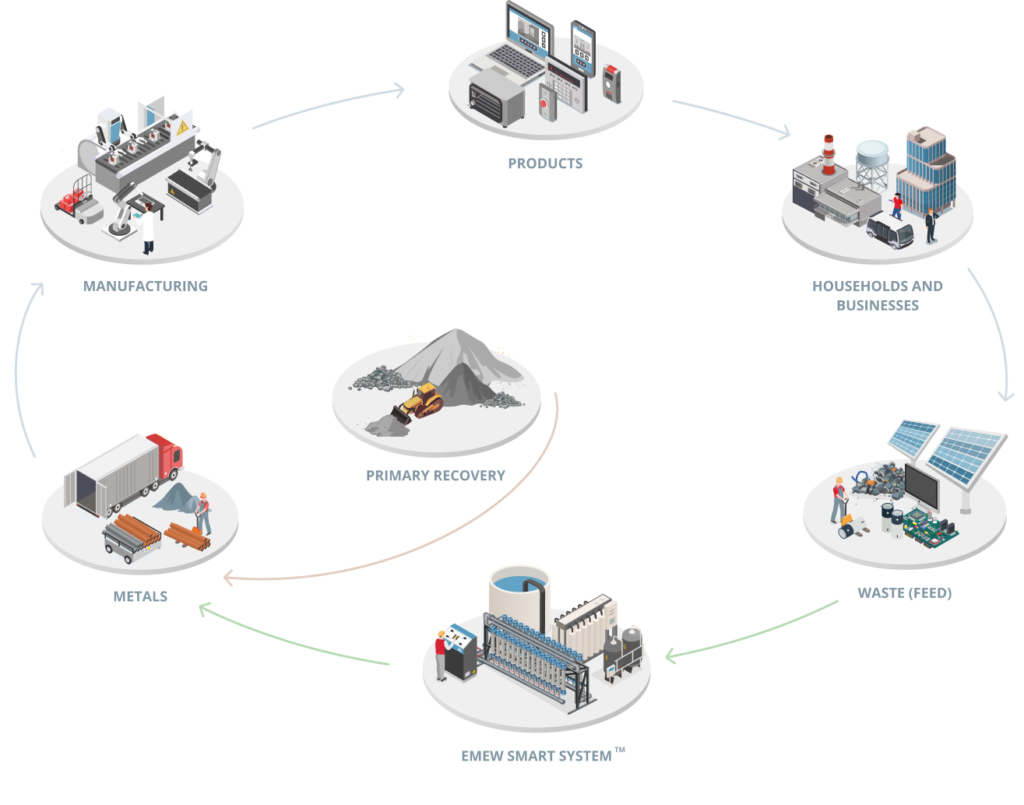

Our vision is of a sustainable future based on the circular economy.

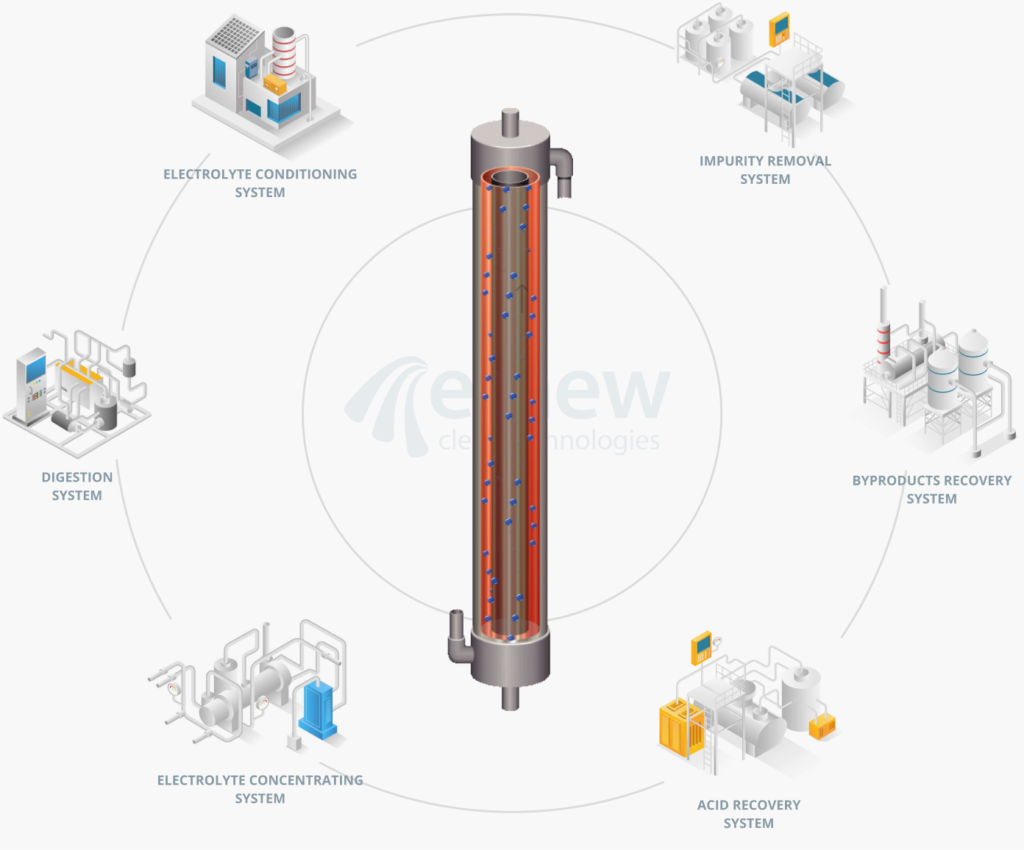

To help fulfill this vision, our mission is to deliver clean technologies for metal recovery under the emew Smart SystemTM. This is a complete suite of hardware, patented technologies, and know-how accumulated over nearly 30 years, incorporating the principles of green chemistry and the invention of the original “vortex” electrowinning technology. As a result, we create value in metal recovery whilst meeting important ESG obligations.

emew Smart SystemTM

The complete suite of technologies incorporated in the emew Smart SystemTM allows us to recover metals from a variety of feeds, including mining ores, electronic waste, silver and copper refining bleed, batteries, solar panels, PGMs, and many more. The output is a saleable metal cathode or powder of the highest purity.

Advantages of the emew Smart SystemTM

Everything we do is designed to help customers with their ESG obligations. Our approach is aimed to improve safety and environmental compliance and create long-term value that mitigates the effects of climate change and resource scarcity.

Conventional electrowinning

State of the art emew Smart SystemTM

Advanced copper recovery technology

The most advanced technology for copper recovery provided by emew features a unique cell design that delivers high-grade saleable cathode (even from secondary liberators) improved current and energy efficiency, improved copper and impurity control over a range of concentrations, recycling of acid, and reduction in effluents.

Revolutionary nickel recovery technology

We have been able to revolutionize the way Nickel and Cobalt are electrowon, and with the clever combination of emew electrowinning and process methodology we are able to recover metals from a variety of feeds including E-Waste, Nickel/Cobalt scrap, Nickel by-products, batteries, refinery bleed, SX/EW bleed and finishing bath.

Featured Resources

Learn how our customers found value in their waste streams and recover base and precious metals in a safe, economical, and efficient way with payback in only 2 years

Meet Our Customers

Meet our team

Our experienced team is committed to helping you achieve your business goals and provide first-class customer service in the areas of environmental stewardship, metal recovery, energy efficiency, and waste water treatment.