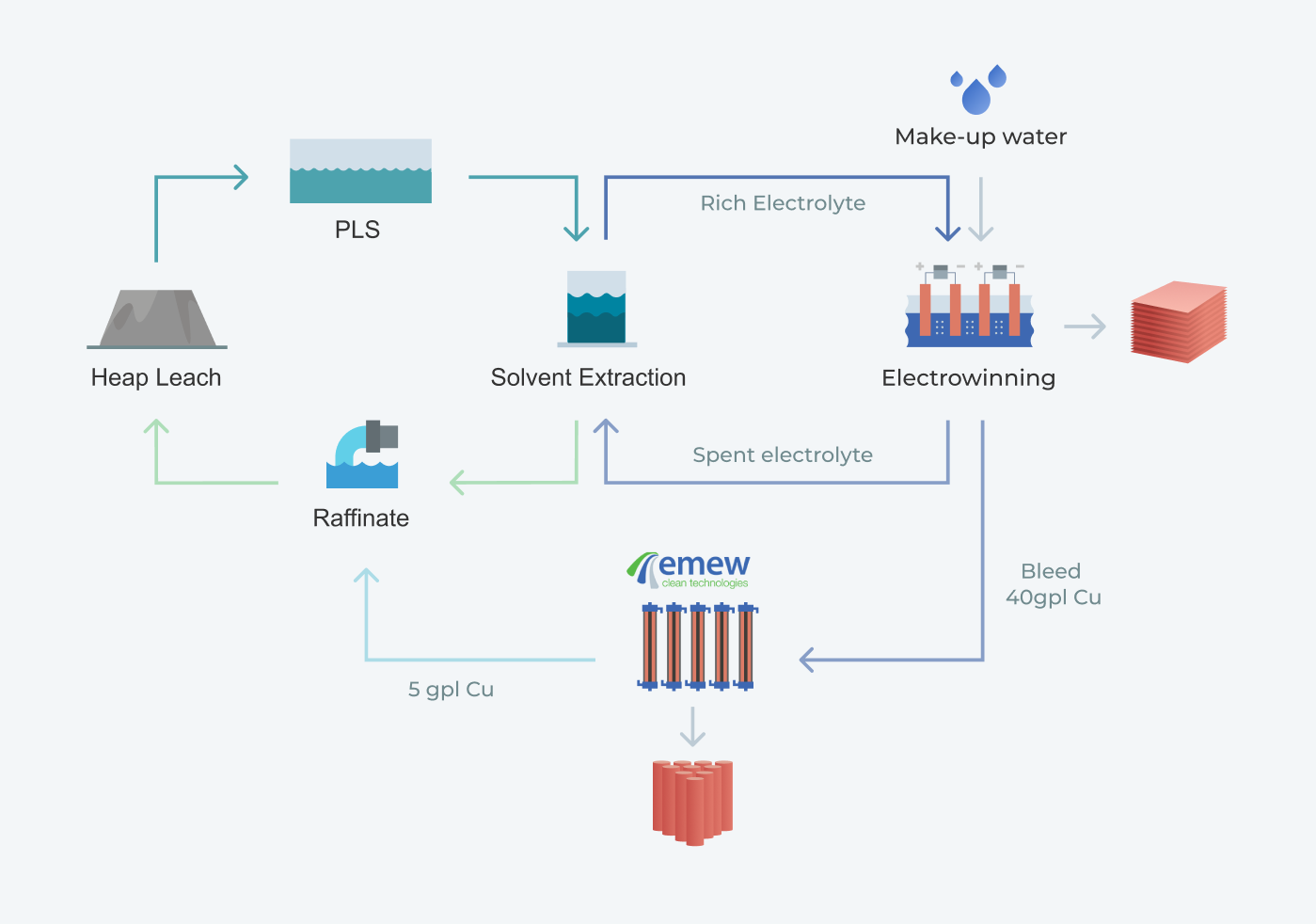

Heap leaching is used around the world to recover copper from low-grade oxide deposits. As with any hydrometallurgical process, there is an intrinsic need to bleed a portion of electrolyte for impurity control.

In the case of SX-EW operations, this bleed often deports to the raffinate pond which negatively affects the leach efficiency in the heap. According to Fick’s Law, this practice negatively affects leaching performance due to the increased cationic load and decreased diffusional flux. By recovering copper cathode directly from the bleed stream using emew prior to sending it on to the raffinate pond, the following benefits can be realized:

• Up to 10% improvement in copper recovery from the heap

• 15-30% reduction in copper tenors in the raffinate

• Lower fresh acid consumption

• Reduced working capital

• Increased copper cathode production

Recovering high-grade saleable copper cathode from SX-EW bleed streams using emew electrowinning decreases copper tenors returning to the heap, enhances leach efficiency and improves overall copper recovery from the heap.

Additionally, as the heap nears the end of its life, recovering the most copper units is critical to ensure profitability and successful decommissioning. The unique emew electrowinning technology enables recovery of more soluble copper units from spent heap leach ores than any other electrowinning technology.